In-Mold Decorations: Elevating Products With Precision and Appearances

In the realm of product layout, the marriage of accuracy and visual appeal holds a vital setting in recording customer focus and commitment. In-Mold Decorations (IMD) have arised as an advanced technique that not only boosts the visual appeal of items yet also ensures a careful integration of layout aspects.

Advantages of In-Mold Decorations

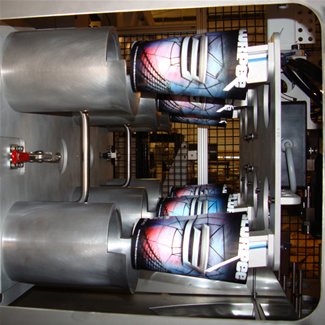

Using in-mold decorations supplies suppliers a cost-effective method to effortlessly integrate detailed layouts onto plastic surfaces during the manufacturing process. This cutting-edge method entails placing a pre-printed film or label right into the mold and mildew before injecting the molten plastic, causing an irreversible combination of the decor with the product. The benefits of in-mold decorations are manifold, starting with the capability to attain high-resolution graphics and in-depth styles that improve the visual charm of the end product. This process eliminates the requirement for additional operations such as paint or post-decoration, enhancing the manufacturing process and lowering manufacturing time and costs.

Along with improving aesthetic appeals, in-mold decors also improve the sturdiness and durability of the design as it comes to be an essential part of the item, as opposed to a surface layer that can disappear over time. The smooth integration of decorations through in-mold techniques guarantees a uniform and consistent appearance across all made things, preserving brand uniformity and high quality requirements - In-Mold Decorations. Generally, the benefits of in-mold decors make it a recommended selection for producers looking to elevate their items with accuracy and aesthetic charm

Accuracy in Design Assimilation

Achieving meticulous layout integration through in-mold decorations needs a keen concentrate on accuracy and interest to detail from the preliminary phases of the production procedure. The success of in-mold decorations hinges on the smooth combination of the style with the product, producing a aesthetically attractive and unified outcome. Accuracy in design combination entails elements such as ensuring the exact positioning of the decoration within the mold and mildew, choosing the ideal materials to accomplish the wanted aesthetic, and maintaining consistency throughout the manufacturing process.

One trick facet of accuracy in design combination is the alignment of the decoration with the product's contours and functions. This needs careful preparation and implementation to guarantee that the layout matches the product's form and enhances its general look. Furthermore, interest to information is vital in keeping the top quality and uniformity of the decors throughout several manufacturing runs, making sure that each product satisfies the highest standards of accuracy and visual appeal. By prioritizing precision in style assimilation, manufacturers can elevate their items and create a long-term perception on customers.

Looks and Visual Impact

With a concentrate on improving the overall appeal of products, the aesthetic appeals and aesthetic impact of in-mold decors play a pivotal role in captivating consumer attention. In today's affordable market, where customers are inundated with choices, the aesthetic charm of a product can be the separating element that influences acquiring decisions. In-mold decors offer a special opportunity to raise the looks of items by offering complex layouts, vivid shades, and seamless surfaces that standard decorating approaches might struggle to accomplish.

The aesthetic impact of in-mold decors extends beyond plain visual appeals; it communicates brand name top quality, identity, and attention to detail. By including aesthetically enticing elements right into item layout, manufacturers can produce a solid brand name existence that resonates with consumers on a subconscious degree. In addition, the precision and uniformity supplied by in-mold decoration techniques make certain that every product fulfills the greatest requirements of aesthetic appeal, enhancing brand name reliability and customer depend on.

Cost-Effectiveness of IMD

IMD minimizes the need for second operations like paint or labeling, saving both time and sources. By incorporating the decor directly right into the molding process, IMD gets rid of the additional steps needed for using decorations post-production. This structured process not only decreases labor prices yet additionally decreases the danger of mistakes or problems that might arise throughout additional enhancing processes.

Moreover, IMD enhances the resilience of decors by enveloping them within the item, guaranteeing a longer-lasting and extra immune coating - In-Mold Decorations. This sturdiness converts right into minimized upkeep and replacement expenses over the product's lifecycle, making IMD a cost-efficient solution for accomplishing remarkable aesthetic appeals and aesthetic allure in production

Sturdiness and Durability

Including in-mold decors not only ensures cost-effectiveness in making processes but also significantly enhances item durability and longevity. The procedure of in-mold design involves the application of graphics or attractive surfaces during the molding process, creating a seamless and integrated style that is protected within the item itself. This protective layer provided by in-mold designs acts as a guard against wear and tear, scrapes, fading, and various other ecological variables that could compromise the appearance and resilience of the item over time.

Products with in-mold decors are understood for their resistance to abrasion, chemicals, and UV direct exposure, making them suitable for applications that visit their website call for long-term efficiency and appearances. Unlike standard surface-applied designs that can peel off or fade with usage, in-mold designs come to be an intrinsic part of the product, ensuring that the design remains intact and vibrant throughout the item's life expectancy. This resilience not just improves the general top quality of the item but also decreases the demand for constant upkeep or substitutes, eventually offering lasting expense savings for consumers and suppliers alike.

Final Thought

The benefits of in-mold decorations are manifold, starting with the ability to attain high-resolution graphics and comprehensive styles that boost the visual charm of the final item.In addition to boosting aesthetics, in-mold designs also boost the toughness and durability of the style as it ends up being an indispensable component of the item, rather than a shallow layer that can wear off over time. In-mold designs supply an one-of-a-kind possibility to boost the visual appeals of items by supplying complex styles, lively shades, and smooth coatings that conventional designing techniques might struggle to achieve.

The procedure of in-mold design involves the application of graphics or attractive finishes during the molding process, creating a smooth and incorporated layout that is safeguarded within the item itself. Unlike typical surface-applied decorations that can peel off or discolor with use, in-mold designs come to be an inherent component of the product, making sure that the layout continues to be undamaged and vibrant throughout the item's life-span.